Introduction

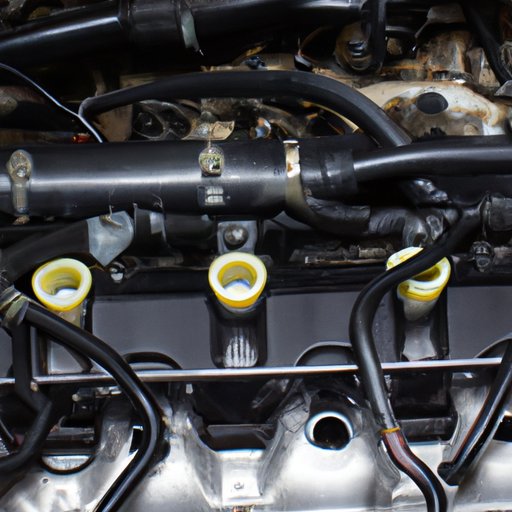

An issue with the engine’s head gasket can quickly turn into a costly repair if left untreated. The head gasket is positioned between the engine block and the cylinder head and acts as a seal for the combustion chambers, preventing coolant and oil from mixing. When the gasket fails, it can cause irreparable damage to the engine. In this article, we’ll explore how to fix a blown head gasket without replacing it.

Use a Sealant

A head gasket sealant can be a saving grace in repairing a damaged head gasket. These sealants are designed to create a temporary seal on minor head gasket leaks, allowing you to avoid more costly repairs.

Description of Head Gasket Sealants

Head gasket sealants are a unique compound that can seal small cracks or leaks in the head gasket. Many of these sealants use a two-part epoxy formula designed to expand and harden when exposed to heat. This expansion allows the sealant to fill gaps and cracks that can cause coolant and oil leaks.

Step-by-step Instructions on How to Use a Sealant

To use a head gasket sealant, follow these simple steps:

- Drain the engine coolant to an appropriate level.

- Clean the engine with degreaser to remove any dirt or oil.

- Add the necessary amount of sealant into the radiator or overflow tank.

- Refill the radiator with coolant and start the engine.

- Let the engine run for the recommended amount of time indicated on the sealant’s instructions.

- Turn off the engine, drain the coolant, and replace it with fresh coolant.

Tips and Precautions

It is important to note that a head gasket sealant is only a temporary fix. While it can help repair a minor leak, if your head gasket issue is severe, you may still need to replace the gasket itself. Additionally, it is vital to carefully read and follow the instructions provided by the sealant manufacturer to avoid any damage to your engine or vehicle.

Check the Coolant System

The coolant system is an integral part of preventing head gasket failure. Issues with the coolant system, such as leaks or low coolant levels, can cause the engine to overheat, leading to head gasket failure.

How to Inspect the Coolant System for Leaks

Inspecting the coolant system for leaks is relatively straightforward. First, visually inspect the hoses and connections for any visible cracks, damage, or leaks. The next step is to pressurize the system by using a pressure testing kit. This will help you identify any hidden leaks. If you find any leaks, replace the damaged parts or gaskets.

How to Fix Coolant Leaks

If you find any leaks in the coolant system, you’ll need to resolve them to avoid future head gasket issues. The solution depends on the severity of the leak, with minor leaks commonly resolved by replacing the damaged hose or clamp. For more severe damage, you may need to replace the radiator or water pump.

Tips to Maintain the Coolant System

To avoid future head gasket issues, it’s important to maintain your coolant system. Regularly flush and replace the coolant according to the manufacturer’s recommendations and ensure that you keep the coolant level in the required range at all times. Additionally, inspect the system for any signs of damage or wear regularly.

Replace Damaged Parts

In some situations, head gasket failure can be caused by other damaged engine components. By inspecting and replacing these parts, you may be able to fix the underlying issue without replacing the head gasket.

Common Parts that can Cause Head Gasket Failure

The most common part to fail includes a faulty thermostat that causes the engine to overheat. A damaged water pump or radiator can also result in overheating and lead to head gasket failure. It’s therefore important to inspect and replace these parts as necessary.

How to Inspect and Replace Damaged Parts

Inspecting and replacing faulty engine components can vary widely, depending on the specific part in question. In general, you’ll need to follow the manufacturer’s guidelines for inspecting and replacing each part. If you’re unsure of how to proceed, it’s best to consult with a qualified mechanic.

Factors to Consider when Replacing Parts

When inspecting and replacing parts that can cause head gasket damage, consider purchasing high-quality OEM or aftermarket parts. Don’t cut corners, as it can end up costing you more in the long run. Choosing high-quality parts ensures that they will last longer and less likely to break, thus reducing the risk of head gasket failure.

Use a Coolant Flush

Flushing the coolant helps to remove any sludge, debris or other pollutants in the coolant system while protecting head gasket health.

What is a Coolant Flush and How it Works

A coolant flush involves removing the old coolant and replacing it with new coolant. This process helps to remove any debris and pollutants that may be present in the cooling system. The coolant flush also ensures that the coolant system is working correctly hence minimizing the risk of head gasket failure.

When to Perform a Coolant Flush

Different manufacturers recommend different intervals for a coolant flush. It’s best to refer to the owner’s manual for information regarding your specific vehicle. Generally, a good rule of thumb is to flush the coolant system every 40,000 to 60,000 miles.

How to Perform a Coolant Flush

To perform a coolant flush, you need to follow these steps:

- Disconnect the lower radiator hose to drain the old coolant.

- Connect a garden hose to the radiator and allow the water to flush through the engine and out the drain.

- Repeat the process until the water running out appears clear.

- Reconnect the lower radiator hose.

- Add the appropriate amount of a 50/50 coolant and water mixture.

- Bleed the air from the system and start the engine.

Drive with Care

Finally, driving carefully is crucial for maintaining a healthy engine and preserving the life of the head gasket.

The Importance of Driving Carefully to Prevent Further Damage

Aggressive driving and hard acceleration create extreme pressure and heat in the engine, eventually leading to head gasket failure. Therefore, it is essential to avoid overheating the engine and overstressing it.

Tips on Driving Habits that can Prolong the Life of Your Head Gasket

To preserve the head gasket life, follow these driving tips:

- Avoid stressing the engine by driving at high speeds or accelerating harshly.

- Follow the manufacturer’s recommendations on the correct fuel to use.

- Ensure that you avoid having the engine run at a high temperature.

- Perform regular maintenance to keep the engine in excellent condition.

Signs to Watch Out for that Indicate a Failing Head Gasket

It’s also crucial to keep an eye out for signs that your head gasket may need repair. These signs include grey or white smoke coming from the exhaust pipe, an engine that frequently overheats, fluctuating coolant levels, and bubbling coolant.

Conclusion

In summary, fixing a blown head gasket without replacing it can be achieved through several different methods. Using a sealant, inspecting and maintaining the coolant system, replacing damaged parts, performing regular coolant flushes, and driving carefully are all crucial steps. It’s essential to understand that these methods are only temporary and diligent maintenance is recommended to prevent further damage.

By following these tips, you can fix a blown head gasket without replacing it, saving hundreds or even thousands of dollars in repair costs.