How to Figure Concrete: The Comprehensive Guide for DIY Projects

Concrete is a versatile and durable building material that can be used for a wide range of DIY projects. However, when it comes to tackling a concrete project, one of the biggest challenges is figuring out the correct amount of concrete required and ensuring its durability. In this article, we’ll cover everything you need to know about figuring concrete, from calculating the required amount to concrete mixtures, tips for durability, testing, and professional finishing advice.

DIY Concrete Calculations – A Beginner’s Guide

The first step to any concrete project is calculating the required amount of concrete, which can be tricky for beginners. You’ll need a few essential tools and equipment, including a tape measure, calculator, and a pencil and paper. Once you have these handy, follow these step-by-step instructions:

- Measure the length, width, and height of the area you want to cover with concrete, in feet.

- Multiply these three numbers to find the cubic feet of concrete required

- Divide the cubic feet by 27 to convert to cubic yards, which is the standard way concrete is sold in the US.

- Order 10-20% more concrete than what you calculated to account for waste, spills, or overfilling the forms.

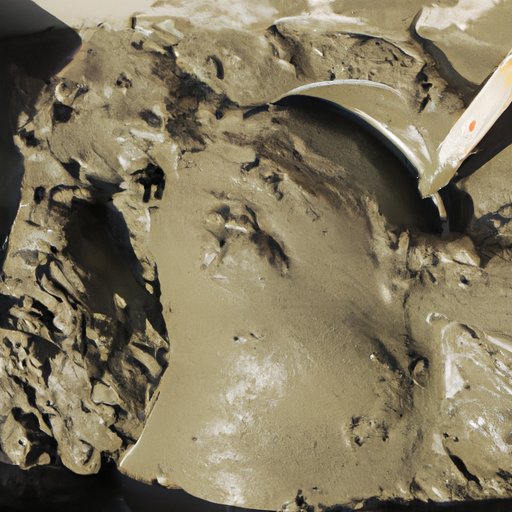

Accompanying images will help you understand the process more efficiently, and you’ll soon master the art of calculating concrete like a pro!

Concrete Mixtures and the Art of Proportions

Understanding the correct proportions of concrete mixtures is crucial to achieving strong and durable concrete. The variations in the proportion of ingredients in the mix can significantly impact the final strength and hardness of concrete. Cement, aggregate, and water are the basic components of concrete, and while the proportion of each element depends on the type of project, the following proportions of ingredients are standard:

- Cement: 10-15% of the total mixture

- Aggregate: 60-75% of the total mixture

- Water: 15-20% of the total mixture

Along with these primary ingredients, you may also need to add admixtures like accelerators, retarders, or water reducers to enhance the concrete’s performance. The type of mixture and the proportion of ingredients depend on the project requirement, concrete strength target, and environmental conditions.

Tips and Tricks to Ensure Durable Concrete

Pouring and finishing concrete correctly is not enough to guarantee its durability; you need to be mindful of the elements that can damage it over time. Here are few tips to ensure durable concrete:

- Proper pouring and curing: Keep the concrete mix moist during the pouring and curing process to allow it to develop optimal strength.

- Avoid excessive water: Excessive water can weaken the concrete, so maintain the water ratio in the mix.

- Ensure proper drainage: If water accumulates around or under the concrete slab, it can cause it to move or sink over time.

- Protect from frost and freeze: If you live in an area with harsh winters, you’ll need to prepare for freezing and thawing cycles that can damage concrete. Use de-icing chemicals appropriately as they can corrode the surface of the concrete.

By following these tips, you can increase the life span of concrete up to 20% easily!

Learning the Basics of Concrete Testing

Whether you work on a DIY project or hire a professional, testing the quality of concrete is critical. Proper testing of concrete includes slump testing, compressive strength testing, and density testing. Here is a brief overview:

- Slump testing: It measures the consistency of the concrete mixture and helps ensure that it’s been mixed with the right amount of moisture and that the slump is as per the requirement.

- Compressive strength testing: This test measures the amount of weight concrete can bear before it cracks or crumbles. It is especially important for structures like bridges, dams, and high-rise buildings.

- Density testing: This measures the weight of the material to gauge the stability of the concrete.

Proper concrete testing allows you to verify that the concrete mix is in line with standard specifications and that it will perform as expected.

Top 10 Concrete Contractor Secrets for the Perfect Finish

While DIY concrete projects are incredibly satisfying, experts’ advice can help you achieve an outstanding concrete finish. The following tips will help you ensure a perfect finish without any hiccups:

- Use the right mix for the project. A mix for a sidewalk is not the same as a mix for a foundation.

- Plan for the season: Concrete sets and cures better in warm and dry weather.

- Keep the surface clean and free of debris

- Seal the concrete after it’s fully cured to protect it from pollutants, oil, and water.

- Be mindful of the tools used for finishing. Use tools meant for the type of project, temperature conditions, and the type of finish expected.

- Be strategic with the placement of control joints to prevent concrete from cracking.

- Pay attention to time. The concrete often starts setting within an hour, which means you’ll need to work quickly to perfect the finish.

- Opt for a slightly rough surface, as it provides better traction for vehicles and people.

- Use admixtures to enhance the performance of concrete and achieve the desired finish.

- Keep extra concrete on hand to fill in any gaps or repair cracks or holes that develop over time.

With these tips, you’ll be able to take your concrete projects to the next level and achieve a professional-style finish!

Conclusion

Concrete is an incredibly versatile and durable material that can withstand harsh environments and last for decades. By learning how to figure concrete accurately, choosing the right mixture, pouring, curing, testing, and perfectly finishing, you can create stunning structures that last. Whether you are a DIY enthusiast or a professional contractor, understanding the ins and outs of figuring concrete is vital to ensuring your projects’ success.