The Ultimate Guide to 3D Printing: From Basics to Advanced Techniques

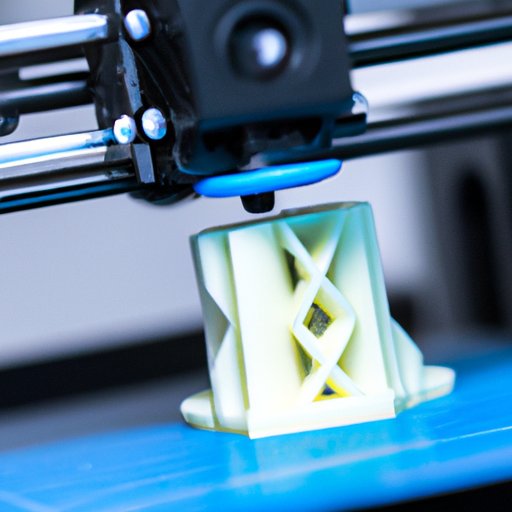

3D printing, also known as additive manufacturing, is a technology that has been around for many years, but it has gained more popularity recently. This is because the technology has become more user-friendly, and the cost of owning a 3D printer is now more affordable. Essentially, 3D printing is a process of building objects by layering material, typically plastic or metal, until the object is complete. In this article, we will delve into 3D printing from basics to advanced techniques, discussing everything from what it is to how to design and print objects.

3D Printing for Beginners

3D printing can be daunting for beginners, but it doesn’t have to be. First, it is essential to understand what 3D printing is. Simply put, 3D printing is building objects from digital designs using various materials such as plastics, metals, and ceramics. Currently, there are different types of 3D printers available on the market, and they vary in size, types of materials they print, and printing technology. Each printer has unique features and capabilities that make them ideal for particular applications.

3D printing has various applications in different industries such as healthcare, architecture, and automotive. It is used to design and produce implants, prosthetics, automotive components, jewelry, and shoes, among other things.

When it comes to 3D printing, some frequently asked questions include the cost of owning a 3D printer, how long it takes to print an object, and the quality of objects produced. Owning a 3D printer will require an initial investment, but the cost has dramatically reduced over the years. Printing time depends on the size and complexity of the object, with smaller objects taking less time to print. The quality of the objects produced depends on the parameters used when printing, such as the layer thickness and printing speed.

A Step-by-Step Guide to 3D Printing

To successfully print an object using a 3D printer, you need to go through a step-by-step process.

Step 1: Choose the Right Printer and Filament

The printer and filament you choose will have an impact on the quality and outcome of your print. Selecting the right printer and filament requires assessing your needs and the project you plan to undertake.

Step 2: Prepare the Printing Bed

Before printing, you need to prepare the printing bed. This involves applying adhesive to the printing bed for the object to adhere to it correctly.

Step 3: Create or Download a 3D File

To print an object, you need a digital file, and you can either create or download it. For people who do not have experience in designing 3D files, downloading files from websites such as Thingiverse would be the best option.

Step 4: Print the Object

Once you have prepared the printing bed and have the 3D file ready, you need to print the object. The printer will read the file and start building the object layer by layer.

Tips to make the process smooth and effective include keeping the printer in a clean and dust-free area, ensuring that the printer’s firmware is up to date, and checking the printer bed level before printing.

The Benefits of 3D Printing

3D printing offers significant benefits, including cost-effectiveness, time-saving, and customization. Traditional manufacturing methods require more time, energy, and costs. This technology has enabled companies to reduce costs by producing parts and objects within their premises, reducing the lead time it takes to produce a full build, and providing a high level of customization.

3D printing has several applications in various industries, such as healthcare, architecture, and automotive. In healthcare, 3D printing is used to create implants, prosthetics, orthopedic devices, and dental work. In architecture, it is used to create scale models and architectural visualizations. In the automotive industry, 3D printing is used to create prototypes, tooling, fixtures, and end-use parts.

Troubleshooting Common 3D Printing Issues

Like any other technology, 3D printing can present problems that require troubleshooting. Some of the most common issues include failed prints, filament issues, and bed adhesion problems.

The solution to these problems depends on the problem itself. For example, if the printer is failing to print due to filament issues, changing the filament’s temperature may fix the problem. If the bed adhesion is the problem, adjusting the bed level or applying adhesives to the bed surface can resolve the problem.

How to Design 3D Printable Objects

Designing 3D printable objects requires one to be conversant with 3D modeling and printing software. Some of the software used in designing include Tinkercad, Fusion360, and SketchUp. It is essential to choose the right software for the project because different software offer different features and tools.

3D designs should be optimized for printing. This means considering factors such as layer thickness, printing speed, and nozzle diameter.

Advanced 3D Printing Techniques

Advanced 3D printing techniques go beyond the basic techniques discussed earlier in the article. Techniques such as using multiple materials, creating movable parts, and printing objects with intricate details require advanced skills and experience.

Advanced 3D printing techniques have various applications and benefits. For example, creating movable parts is essential in creating mechanical parts such as gears and levers. Printing objects with intricate details is useful in creating jewelry, architectural models, and other items that require detail.

Conclusion

In conclusion, 3D printing offers various advantages, and its popularity will continue to grow as the technology advances. This guide has provided you with a comprehensive guide to 3D printing, covering topics from basics to advanced techniques. Now that you have learned how to 3D print, you can explore the possibilities of this exciting technology.