I. Introduction

Sublimation printing has become increasingly popular in recent years, offering an efficient and cost-effective way to transfer high-quality images and designs onto a variety of surfaces. While sublimation is typically associated with fabrics and other textiles, it is also possible to sublimate on wood. In this article, we will explore the ins and outs of sublimating on wood, including tips and tricks for optimal results, DIY project ideas, and common misconceptions.

II. A Guide to Wooden Sublimation: Tips and Tricks for Flawless Results

When it comes to sublimating on wood, it is crucial to use the right transfer paper. Sublimation paper specifically designed for wood has a unique coating that ensures a strong bond between the ink and wood fibers. In addition, wood requires a higher temperature and longer pressing time compared to other sublimation surfaces. For best results, we recommend a temperature of 400°F and pressing time of 60 seconds.

Many factors can contribute to less-than-ideal results when sublimating on wood. One common issue is a lack of consistency in heat and pressure across the surface, resulting in a blurry or faded image. It is essential to use a flat, even surface when pressing the transfer paper onto the wood, and to apply adequate pressure. When sublimating on larger pieces of wood, be sure to use a heat press with a larger surface area to ensure consistent heat and pressure distribution.

III. Why Wood is the Next Big Thing in Sublimation

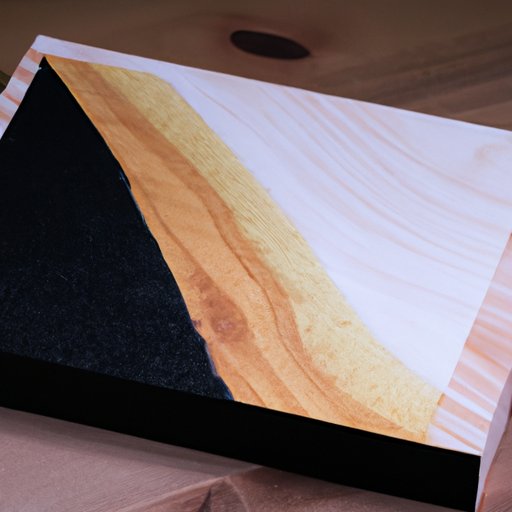

Sublimating on wood offers unique benefits and possibilities that other surfaces cannot match. The natural grain of wood creates a unique, organic texture that adds character and depth to images and designs. Additionally, wood is a versatile material that can be used to create a wide range of products, from personalized signs and coasters to phone cases and jewelry.

Compared to popular sublimation surfaces like metal and ceramic, wood is more forgiving in terms of surface imperfections. Scratches and other blemishes can be sanded out before sublimation, resulting in a smooth, even surface. Wood is also less likely to crack or chip than ceramics, and unlike metal, it is not prone to condensation or rust.

IV. DIY Wood Sublimation: How to Create Personalized Gifts and Decor

One of the best things about sublimating on wood is that it is accessible for DIY projects. With a relatively low investment in equipment and supplies, anyone can create personalized, one-of-a-kind wooden products. Some popular DIY projects include custom wood signs, photo frames, keychains, and coasters.

To get started, you will need a sublimation printer, transfer paper, a heat press, and of course, wood. In order to ensure a smooth surface for sublimation, it is recommended to use smooth, flat pieces of wood with minimal texture. To create a personalized wood sign, simply print out your desired image onto the sublimation paper, press it onto the wood with the heat press, and voila! You have a beautiful, custom wooden sign.

V. Avoiding Mistakes: Common Wood Sublimation Misconceptions Debunked

There are several common misconceptions when it comes to sublimating on wood. One of the most persistent myths is that sublimation ink cannot adhere properly to wood fibers. As we mentioned earlier, this is simply untrue – by using the right transfer paper and following the proper pressing guidelines, you can achieve high-quality, long-lasting sublimation results on wood.

Another common mistake is assuming that wood with visible texture or grain cannot be sublimated. While it is true that wood with a lot of texture may not produce the same level of detail and resolution as a smooth, flat surface, that does not mean it cannot be sublimated at all. In fact, wood with a prominent grain can create a unique, rustic effect that many people find appealing.

VI. Breaking Down the Cost of Wooden Sublimation: Is it Worth It?

One of the most important considerations when deciding whether to add sublimation on wood to your product offerings is the cost. While sublimation equipment and supplies can be pricey, the potential return on investment can make it more than worth it. Personalized wooden products are in high demand in a variety of markets, from home decor to gifts and souvenirs.

The cost of materials and equipment will vary depending on the type and amount of wood you plan to use, as well as the size and volume of your production. In general, a sublimation printer can cost anywhere from a few hundred to a few thousand dollars, while transfer paper and ink will cost several hundred dollars per pack. However, keep in mind that the initial cost of equipment and supplies will decrease over time as you produce more items and gain experience.

VII. Conclusion

Sublimating on wood offers a unique and versatile way to create personalized, high-quality products. By following guidelines for optimal results, DIY enthusiasts and business owners alike can take advantage of the benefits and possibilities of sublimation on wood. Whether you’re interested in creating custom wooden signs, coasters, or other products, or simply curious about the possibilities of sublimation on wood, we hope this guide has been informative and inspiring.